Archive

Getade Environnement : soluciones naturales con efectos secundarios para asegurar el potencial de los cultivos

“Personalmangel im Gastgewerbe sorgt weiterhin für hohen Bedarf an verarbeiteten Produkten” Belgisches Atelier Claessens feiert 5-jähriges Jubiläum FreshPlaza

Belgisches Atelier Claessens feiert 5-jähriges Jubiläum

“Personalmangel im Gastgewerbe sorgt weiterhin für hohen Bedarf an verarbeiteten Produkten”

Am 1. März feiert das Atelier Claessens sein fünfjähriges Bestehen als gezielte Erweiterung von Groothandel Claessens. Das Atelier, das sich ganz auf das Waschen von Salaten und das Schneiden und Verarbeiten von Obst und Gemüse konzentriert, sollte als eine Unterstützungsinitiative für Köche dienen. “Wir wollen den Köchen bei ihrer täglichen Arbeit helfen und ihnen vor allem ermöglichen, Zeit zu sparen, ohne dass die Qualität darunter leidet”, erklärt Brent Peeters von Groothandel Claessens.

“Effizienz und fachmännisches Können müssen Hand in Hand gehen. Gerade in einer Zeit, in der es für viele Gastronomiebetriebe schwierig ist, genügend Personal zu finden, erweist sich diese Unterstützung als kein überflüssiger Luxus. Mit dem Einkauf von geschnittenem Gemüse können wir Köchen viele Vorteile bieten, wie Zeitersparnis, geringerer Bedarf an kompetentem Personal, einfache Preisberechnung, weniger Abfall/Verschwendung, HACCP-Konformität, konstante Qualität und Schnitt. Dass dies geschätzt wird, merken wir auch an dem anhaltenden Wachstum, das wir Jahr für Jahr erzielen”, erklärt er. In dieser Hinsicht konzentriert sich das Atelier Claessens ausschließlich auf den belgischen Markt.

“Wir arbeiten mit zwei Systemen. Einerseits haben wir feste Lagerartikel. Produkte, die standardmäßig geschnitten und verfügbar sind. Andererseits bieten wir Artikel auf Bestellung an. Köche können bestimmte Produkte oder bestimmte Schnittarten anfordern. Wenn etwas nicht standardmäßig in unserem Sortiment enthalten ist, prüfen wir, was möglich ist, und machen uns konkret daran, es zu realisieren. Diese Flexibilität ist für uns sehr wichtig.”

Spargel schälen

Das Angebot passt sich den Jahreszeiten an. Mit dem nahenden Frühling beginnt das Atelier Claessens zum Beispiel wieder mit dem Schälen von Spargel, einem ausgesprochenen Saisonprodukt, das jedes Jahr sehr gefragt ist. “Früher haben wir zum Beispiel auch Schwarzwurzeln geschält. Einige Produkte, wie beispielsweise Karotten, verarbeiten wir das ganze Jahr über, aber andere sind wirklich saisonal. Wir passen unser Angebot bewusst an das Marktgeschehen an und gehen immer von den Bedürfnissen der Kunden aus.”

Das Wachstum der vergangenen fünf Jahre lässt sich auch in Zahlen ausdrücken. Heute arbeiten 25 Mitarbeiter in der Produktion. “Aufgrund der anhaltenden Nachfrage prüfen wir derzeit den Aufbau eines Teams, das Tag und Nacht arbeitet. Wir werden diese Nachtschicht im Jahr 2026 einführen, damit wir kontinuierlich schneiden und verarbeiten können. Das wäre ein großer Schritt nach vorn und zeigt vor allem, dass der Bedarf auf dem Markt nach wie vor hoch ist.”

Qualität

Mit dem fünften Jahrestag wird das Hauptaugenmerk in den kommenden Jahren auf der Optimierung und Qualitätskontrolle liegen. Größere strukturelle Veränderungen sind nicht sofort geplant, aber die Verfeinerung und Verbesserung bleibt ein ständiges Ziel. “Das fünfte Jubiläum ist für uns in erster Linie ein Anlass, den eingeschlagenen Weg zu reflektieren. Gleichzeitig blicken wir nach vorn und überlegen, wie wir unseren Betrieb noch effizienter gestalten können.”

Laut Brent zeichnet sich Atelier Claessens vor allem durch die Kombination von Qualität und einer breiten Produktpalette aus. “Wir bieten eine breite Palette von Produkten an, und das ist gleichzeitig unsere größte Herausforderung. Bei einem so umfangreichen Sortiment muss jeder im Team die verschiedenen Produkte und Schneidemethoden genau kennen. Wir sorgen dafür, dass alles richtig gemacht wird und dass die Qualität gleich bleibt. Mit unserem jetzigen Team schaffen wir es, diesem breiten Leistungsangebot gerecht zu werden und gleichzeitig flexibel auf die Wünsche unserer Kunden einzugehen.”

Der Großhandel Claessens ist während der Tavola 2026 vom 15. bis 17. März am Stand 1304 zu finden.

Weitere Informationen:

Brent Peeters

Groothandel Claessens

Kielsbroek 23

2020 Antwerpen, Belgien

Tel: +32 (0) 3 237 44 29

contact@groothandelclaessens.be

www.groothandelclaessens.be

Asperges : quand l’intelligence artificielle redéfinit les standards du calibrage par Besnard Père & Fils et FreshPlaza

Antoine Besnard, Besnard Père & Fils :

Asperges : quand l’intelligence artificielle redéfinit les standards du calibrage

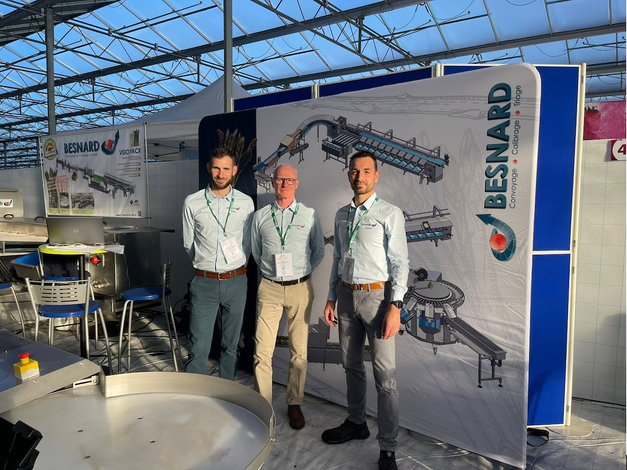

Dans l’univers exigeant de l’asparagiculture, où la précision du tri et la régularité des calibres conditionnent directement la valorisation des lots, la fiabilité des outils industriels est déterminante. Depuis 1965, Besnard Père & Fils accompagne les producteurs avec des solutions de convoyage, calibrage et triage développées en interne. Implantée à Bazouges-Cré-sur-Loir, dans la Sarthe, l’entreprise familiale revendique près de 60 ans d’expérience et poursuit aujourd’hui un travail de modernisation technologique centré sur l’intégration de l’intelligence artificielle.

Un savoir-faire historique construit au plus près du terrain

Depuis sa création, Besnard Père & Fils conçoit, fabrique et installe des équipements dédiés aux produits agricoles, avec une spécialisation marquée dans l’asperge.

« Nous avons toujours travaillé en lien étroit avec les producteurs pour proposer des machines adaptées à leurs contraintes réelles », explique Antoine Besnard.

« Notre ancrage historique s’est construit autour d’une ingénierie robuste et d’une maîtrise complète de la chaîne de conception. Le développement mécanique et électronique est réalisé en interne, ce qui permet des ajustements précis en fonction des spécificités des exploitations et des cahiers des charges commerciaux ».

Être un constructeur français constitue également un atout dans un contexte où la proximité, la réactivité du service technique et la compréhension des normes locales jouent un rôle clé.

Cette implantation nationale facilite les échanges avec les producteurs et l’adaptation des équipements aux évolutions réglementaires et structurelles du marché européen.

L’innovation comme moteur de développement

Si l’entreprise s’inscrit dans la durée, elle affirme ne pas se reposer sur son héritage.

Une part significative de son activité est consacrée à la recherche et développement, avec un objectif clair : améliorer la performance du tri tout en répondant aux enjeux de main-d’œuvre et de compétitivité.

« Le tri de l’asperge devient de plus en plus exigeant. Les critères qualitatifs se multiplient et les attentes des marchés se précisent », souligne Antoine Besnard. « Cette évolution pousse à développer des outils capables d’aller au-delà des seuls paramètres de de couleurs, diamètres, longueurs ».

L’intelligence artificielle au service du tri des asperges

Depuis deux ans, Besnard Père & Fils travaille à l’intégration de modules d’intelligence artificielle dans ses calibreuses électroniques. Une évolution technologique qui pourrait modifier en profondeur les standards du tri.

L’objectif est d’affiner l’analyse des asperges traitées : « Nous cherchons à détecter davantage de critères qualitatifs et à automatiser des décisions qui, jusqu’à présent, reposaient en partie sur l’appréciation humaine. »

Grâce à l’IA, les machines pourraient identifier plus finement certains défauts, analyser des textures ou encore adapter les paramètres de tri en temps réel en fonction des lots. Cette approche vise à améliorer l’homogénéité des colis, à limiter les pertes et à optimiser le rendement global des lignes.

Pour la filière, les perspectives sont multiples : qualité de tri renforcée, meilleure valorisation commerciale et réduction de la variabilité entre opérateurs.

Vers une nouvelle génération de calibreuses

Si tous les développements ne sont pas encore dévoilés par l’entreprise, des prototypes sont actuellement testés. Ils laissent entrevoir des calibreuses électroniques plus rapides et dotées d’une capacité d’analyse accrue. « Les enjeux de productivité et de disponibilité de la main-d’œuvre nous obligent à repenser certains standards », indique Antoine Besnard. L’automatisation avancée apparaît comme une réponse aux contraintes structurelles du secteur, tout en maintenant un niveau d’exigence élevé sur la qualité finale.

À l’heure où la modernisation des outils de conditionnement devient stratégique pour les producteurs d’asperges, Besnard Père & Fils poursuit son évolution en combinant expérience industrielle et technologies émergentes. L’entreprise entend ainsi accompagner la filière dans ses transformations, en proposant des solutions adaptées aux réalités du terrain et aux attentes des marchés.

Pour plus d’informations :Antoine Besnard

Besnard Père & Fils

Bazouges-Cré-sur-Loir

Tél. : 02 43 94 09 82

a.besnard@besnard-ste.fr Date de publication: mar. 3 mars 2026

Edible coating and labelling reduce plastic and extend shelf life by Multivac and FreshPlaza

Edible coating and labelling reduce plastic and extend shelf life

How can the shelf life of fruit and vegetables be extended while reducing plastic consumption? AgroSustain, an agritech company developing solutions for pre- and postharvest, and Multivac, a manufacturer of labelling systems, present a joint approach combining edible coatings with packaging technologies.

AgroSustain, based in Switzerland, has developed Afondo™, an edible coating designed to preserve the quality of fresh produce after harvest. Afondo is applied directly after harvest on existing packaging lines using standard spraying and buffing technologies. It adheres to the fruit’s natural wax layer and forms a thin, breathable barrier on the surface. This layer slows respiration and moisture loss while allowing natural processes such as ripening to continue.

Afondo is positioned as a replacement for conventional waxes and coatings and can extend shelf life in cold storage by up to three weeks and at retail by three to five days, depending on the crop. It is designed to preserve natural ripening without altering taste, appearance, or texture.

Multivac presents two packaging systems in which trays are closed and labelled simultaneously: Topclose™ and Topwrap™.

Topclose combines cardboard trays with a cellulose-based self-adhesive label that closes the tray along the rim, protecting the contents from removal or falling out. This system results in plastic-free packaging and is processed on the L 330 conveyor belt labeller with a capacity of up to 250 packs per minute. It is used for products such as blueberries, raspberries, and gooseberries.

Topwrap uses a label that wraps over the top and along two sides of the tray, enabling rimless trays to be closed. Cardboard or corrugated trays combined with a paper or cellulose label create plastic-free packaging. This process runs on the L 310 conveyor belt labeller with a capacity of up to 150 packs per minute and is suitable for products such as tomatoes, apples, potatoes, mushrooms, and strawberries.

The collaboration combines edible coating technology with packaging systems as a response to food waste and plastic reduction in fresh produce supply chains.

For more information:

For more information:

Aileen Fleer

Multivac

Tel: +49 (0) 5224 931 1037

Email: aileen.fleer@multivac.de

www.multivac.com Publication date: Mon 2 Mar 2026

Prolonger la durée de conservation des fruits et légumes tout en réduisant la consommation de plastique par AgroSustain et MULTIVAC et FreshPlaza

AgroSustain et MULTIVAC développent des solutions intelligentes pour préserver la fraîcheur

Prolonger la durée de conservation des fruits et légumes tout en réduisant la consommation de plastique

Comment peut-on prolonger la durée de conservation des fruits et légumes tout en réduisant la consommation de plastique? AgroSustain et MULTIVAC répondent à cette question avec une approche commune qui combine la fraîcheur naturelle avec des technologies d’emballage durables.

La fraîcheur naturelle rencontre un emballage durable

AgroSustain est une société suisse de technologie agricole qui a développé et lancé AfondoTM – un revêtement breveté et comestible qui maintient la qualité des fruits et légumes frais après la récolte. Afondo est appliqué aux lignes d’emballage existantes au moyen de technologies de pulvérisation et de polissage immédiatement après la récolte et adhère naturellement à la propre couche de cire du fruit, créant une barrière protectrice invisible et respirante à la surface. En formant cette fine couche d’étanchéité, Afondo aide à ralentir la respiration (respiration) et la perte d’humidité sans bloquer les processus physiologiques naturels tels que la maturation.

L’un des principaux avantages d’Afondo est le remplacement des cires et revêtements conventionnels. En outre, la durée de conservation dans le magasin froid peut être prolongée jusqu’à trois semaines et la durée de conservation dans le commerce de trois à cinq jours (selon le type de culture). En outre, la méthode est vérifiable pour maintenir le processus de maturation naturelle sans changer le goût, l’apparence ou la texture.

En outre, MULTIVAC, fabricant de systèmes de marquage innovants, présente deux solutions intelligentes pour économiser des ressources et des emballages attrayants, dans lesquelles les coques sont simultanément fermées et marquées: TopCLOSETM et TopWRAPTM.

TopCLOSETM & TopWRAPTM

Le procédé TopCLOSETM combine des plateaux de carton avec une étiquette auto-adhésive en cellulose, qui ferme solidement la coque par le haut au bord et protège de manière fiable le contenu du retrait ou de la chute. Il en résulte un emballage entièrement sans plastique. Le traitement est effectué sur l’étiqueteuse à bande transporteuse L 330 d’une capacité allant jusqu’à 250 paquets par minute. Cette solution est particulièrement adaptée pour l’emballage de fruits à baies délicats tels que les myrtilles, les framboises ou les groseilles.

TopWRAPTM est une solution durable et flexible dans laquelle l’étiquette ferme le plateau d’en haut et sur deux surfaces latérales – et peut donc également être fermée par des plateaux sans bord circonférentiel. La base est en carton ou en plateau ondulé. En combinaison avec une étiquette de papier ou de cellulose, un emballage entièrement sans plastique est produit. Le traitement est effectué sur l’étiquette à bande transporteuse L 310 d’une capacité allant jusqu’à 150 paquets par minute – parfait pour les produits tels que les tomates, les pommes, les pommes de terre, les champignons et les fraises.

Qu’il s’agisse de TopCLOSETM ou de TopWRAPTM, les deux solutions montrent comment la technologie d’étiquetage moderne peut contribuer activement à plus de durabilité: moins de plastique, de haute fonctionnalité et une forte présence de la marque. Et tout cela sans machine d’emballage complexe.

Réduction du gaspillage alimentaire et utilisation des matériaux

La collaboration entre AgroSustain et MULTIVAC répond à deux des principaux défis dans les chaînes d’approvisionnement alimentaires fraîches d’aujourd’hui: réduire le gaspillage alimentaire et utiliser moins d’emballages plastiques. En combinant la technologie de revêtement comestible avec des solutions d’emballage avancées, ce partenariat démontre que des alternatives viables sont disponibles pour maintenir la qualité du produit tout en réduisant l’impact environnemental.

Il souligne comment l’innovation, la collaboration intersectorielle et une approche ouverte peuvent conduire à des solutions pratiques et évolutives. AgroSustain et MULTIVAC invitent les partenaires tout au long de la chaîne de valeur à contribuer à façonner le changement et à développer conjointement de nouvelles voies pour un avenir plus durable des systèmes de fraîcheur.

Informations complémentaires:

www.multivac.de

https://www.agrosustain.ch/

Biochar gains ground in Spain as a regenerative soil amendment with agricultural and urban uses by Livingchar and FreshPlaza

Biochar gains ground in Spain as a regenerative soil amendment with agricultural and urban uses

The need to regenerate agricultural soils and reduce the carbon footprint of production systems is driving interest in solutions that not only nourish crops but structurally transform how soils function. In this context, biochar, a plant based charcoal obtained through pyrolysis, is beginning to find its place in Spain as a regenerative amendment, with applications ranging from professional agriculture to urban arboriculture.

At the cooperative Carbón Vivo, promoter of the LivingChar brand, the team works with biochar produced from pine wood and certified under the European Biochar Certificate, which guarantees both process sustainability and product safety. “Biochar is an organic carbon material whose purpose is to improve the physical, chemical and biological properties of soil and act as a carbon sequestration tool,” explains Abel Zahínos, one of the project’s promoters.

More than carbon, soil infrastructure

“Our biochar contains more than 80 percent carbon and acts as a soil regenerator by restoring a key mineral, carbon, which many Spanish soils have lost due to intensive agronomic practices, high temperatures and reduced water availability. Unlike conventional fertilizers, biochar does not directly supply NPK,” he notes, “instead it improves soil structure, cation exchange capacity and the management of water and nutrients”.

“An ideal soil is made up of roughly 25 percent water, 25 percent air, and the remainder mineral fraction and organic matter. In degraded or compacted soils, those pores collapse and the capacity to store and properly manage the water and oxygen that plants need for their physiological functions is lost,” he explains. “That is why it is so important to provide soils with a structure that ensures proper circulation of water and gases, elements that are essential for crops to thrive and to be resilient to climate change”.

In this respect, biochar is particularly valuable because of its ability to increase plant available water in soils, the fraction of stored water that roots can extract and use for growth. “According to trials carried out with the Universidad Politécnica de Madrid, conventional compost provides around 7 percent plant available water, while biochar offers more than 50 percent. This allows for a significant improvement in soil water efficiency, a critical factor for Mediterranean crops”.

Less leaching, higher efficiency

Another key property of biochar is its high cation and anion exchange capacity. “In practical terms, it acts as a retention structure that binds nutrients and reduces losses through leaching. Nitrate losses can be reduced by up to 60 percent. This not only improves plant uptake, but also helps optimise fertiliser use and reduce the environmental impact linked to aquifer pollution”.

On this basis, LivingChar has developed solutions such as Compostchar, a regenerative fertiliser combining organic compost, biochar and rock minerals, and Arbochar, designed for woody crops and long term plantations. “The goal is to permanently improve soil conditions from the moment the crop is established”.

In addition, the biochar production process through pyrolysis allows the carbon previously captured by plants during photosynthesis to be stabilised. “Each tonne of our biochar sequesters up to 2.9 tonnes of CO₂ equivalent. Unlike natural biomass decomposition, which returns carbon to the atmosphere, biochar stabilises it in the soil for estimated periods ranging from 700 to 3,000 years”.

“In fact, the Intergovernmental Panel on Climate Change recognizes it as one of the currently available technologies with net carbon removal, adding a climate dimension to its agronomic application”.

From fields to cities

Beyond agriculture, biochar is also gaining prominence in urban gardening and arboriculture projects. “Cities such as Stockholm began incorporating biochar into their plantings after detecting mortality and disease rates of up to 80 percent in urban trees due to soil compaction. Since 2008, all new trees have been planted with biochar, achieving survival rates close to 100 percent,” Abel shares.

In Spain, LivingChar is working with municipalities such as Barcelona and Córdoba to improve urban soils. “The problem in cities is compaction. Soil loses its ability to properly manage the air and water that trees need, and roots cannot develop. A tree, and plants in general, can die both from lack of oxygen and from lack of water,” he points out.

An emerging market with room to grow

Although awareness of biochar has increased over the past five years, adoption in professional agriculture remains limited. “At LivingChar we recognise that there is still a strong need for outreach and for clear differentiation in quality, since raw material, production process and certification make a substantial difference to the final product”.

“At present, we are focusing on the Spanish market, with a grower focused model based on soil analysis and personalized technical advice. But we are convinced that wider use of biochar is only a matter of time”.

For more information:

For more information:

Livingchar

C/ Margarit 37

08004 Barcelona

T. (+34) 670 585 159

hola@livingchar.com

https://www.livingchar.com

Frontpage photo: © Livingchar

Le nouveau défi relevé par Maf Roda :

Utiliser le calibrage de la datte comme outil de valorisation par FreshPlaza

Le nouveau défi relevé par Maf Roda :

Utiliser le calibrage de la datte comme outil de valorisation

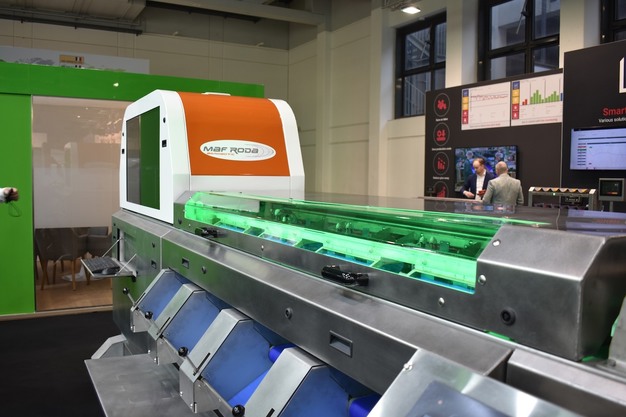

Maf Roda a frappé fort cette année encore à l’occasion de l’édition 2026 de Fruit Logistica, en dévoilant une innovation qui n’est pas passée inaperçue dans les allées du salon. Avec le lancement de sa toute nouvelle solution dédiée au tri et au calibrage des dattes, l’entreprise s’attaque à l’un des produits les plus complexes de la filière fruits. Cette machine marque une avancée technologique majeure, tant par sa capacité à gérer des fruits à très fort taux d’humidité que par son approche globale du nettoyage, du tri optique et de la valorisation des lots. Un développement stratégique pour le groupe, qui confirme une nouvelle fois son rôle de pionnier sur le marché du post-récolte. Vincent Boulbès au Fruit Logistica 2026

Vincent Boulbès au Fruit Logistica 2026

Un défi technologique relevé sur l’un des fruits les plus complexes de la filière

« La datte est sans doute l’un des fruits les plus compliqués à trier et à calibrer », explique Vincent Boulbès, export Sales chez Maf Roda. « Fragile, collante, très variable en calibre, en poids et en humidité, elle impose des contraintes techniques fortes. Fort de notre expertise dans le calibrage de nombreux fruits et légumes, nous avons réussi à développer cette nouvelle machine en seulement deux petites années ». Une prouesse rendue possible par l’adaptation de technologies éprouvées à un produit aux exigences très spécifiques.

Un double contrôle qualité pour une précision inédite

La solution développée par Maf Roda repose sur la combinaison de la calibreuse PLUMONE P50 et des technologies Datescan et Insight. Le contrôle qualité externe détecte avec une grande précision les défauts visibles, tels que les décollements de peau ou les couronnes asséchées. En parallèle, le contrôle qualité interne, via la technologie Insight, analyse la qualité interne des fruits de manière non destructive. « Nous sommes capables de mesurer le taux d’humidité et de détecter la pourriture interne du fruit, notamment des contaminations fongiques », précise Vincent Boulbès.

Trois classes d’humidité pour transformer le tri en outil de valorisation

Grâce à cette analyse interne, les dattes sont réparties en trois catégories : trop humides, prêtes à emballer et trop sèches. « C’est là que la machine devient particulièrement intéressante, car elle permet d’éviter les pertes. Les fruits écartés peuvent être revalorisés en étant réhumidifiés ou séchés afin de revenir dans le bon standard », explique Vincent Boulbès. Cette gestion fine de l’humidité permet aux opérateurs de revaloriser l’ensemble des lots, tout en sécurisant une qualité homogène.

Une pesée physique individuelle, une véritable rupture sur le marché

Autre particularité forte de cette solution : la pesée physique de chaque datte. « Nous sommes aujourd’hui les seuls à proposer un système de pesée mécanique individuelle du fruit », affirme Vincent Boulbès. Cette technologie permet de combiner précisément calibre et poids afin d’obtenir une uniformité parfaite des colis finis. Un critère devenu central pour les opérateurs positionnés sur les marchés premium, où l’homogénéité visuelle et pondérale est déterminante.

Un système de nettoyage conçu pour des fruits collantsMais Maf Roda ne s’est pas contenté de répondre aux seuls enjeux de productivité et de tri. Le groupe a également porté une attention particulière à l’ergonomie et à la facilité d’utilisation de la machine, notamment à travers un système de nettoyage de pointe, spécifiquement pensé pour répondre aux contraintes de traitement d’un produit aussi exigeant que la datte : « Nous travaillons sur un produit collant, avec un taux d’humidité très élevé, ce qui implique un nettoyage extrêmement performant », souligne Vincent Boulbès. La ligne intègre des phases de lavage par buses à eau, suivies d’un séchage par couteaux d’air, afin d’éliminer poussières, sable et noyaux. Entièrement construite en inox, la machine se distingue également par sa robustesse et par une maintenance facilitée.

Une solution clé en main au service des marchés haut de gamme

Du lavage au calibrage optique, de la pesée individuelle à l’emballage, Maf Roda propose avec cette machine un process complet, pensé pour répondre aux exigences croissantes du marché des dattes premium. Les résultats seraient déjà très satisfaisants. « Nous avons obtenu de très bons résultats dès les premières mises en œuvre. Cette calibreuse répond parfaitement aux besoins des clients qui cherchent à proposer des colis haut-de-gamme, où uniformité et régularité sont indispensables pour obtenir une valorisation maximale du produit ».

Pour plus d’informations :

Vincent Boulbès

Maf Roda

Tél. : 05 63 63 27 70

https://www.mafroda.com/fr-fr/fruits-et-legumes/datte/ Date de publication: jeu. 12 févr. 2026